The prime mover in a synchronous generator is the component that drives the rotor. It can be a turbine or an engine.

The prime mover is crucial as it provides the mechanical energy needed to generate electricity. Without a properly functioning prime mover, the synchronous generator would not be able to produce power efficiently. In this blog post, we will explore the importance of the prime mover in synchronous generators and how it contributes to the overall performance of the system.

Additionally, we will discuss the different types of prime movers commonly used in synchronous generators and their unique characteristics. Understanding the role of the prime mover is essential for ensuring the reliable operation of synchronous generators in various applications.

Introduction To Synchronous Generators

The prime mover in synchronous generators refers to the mechanical input source that drives the rotor to produce electrical energy. Common prime movers include steam turbines, gas turbines, and diesel engines. These generators are widely used in power plants and industrial settings due to their stable output and efficient operation.

The Role Of Prime Movers

Prime movers play a crucial role in the operation of synchronous generators. They are responsible for converting mechanical energy into electrical energy, thus driving the generator to produce electricity.

Basics Of Synchronous Generation

Synchronous generators are vital components in power generation, producing electricity by converting mechanical energy into electrical energy. They operate based on the principle of electromagnetic induction, where the movement of a conductor within a magnetic field induces an electrical current.

Credit: www.semanticscholar.org

Types Of Prime Movers

A prime mover is a device that generates mechanical energy to drive a synchronous generator. There are several types of prime movers commonly used in synchronous generators.

Steam Turbines

Steam turbines are a popular choice for generating electricity due to their high efficiency.

Hydro Turbines

Hydro turbines harness the power of flowing water to generate electricity in synchronous generators.

Combustion Engines

Combustion engines, such as diesel or gas engines, are used as prime movers in synchronous generators for smaller-scale power generation.

Energy Conversion Process

The energy conversion process in a synchronous generator involves the transformation of mechanical energy into electrical energy. This conversion is made possible by the prime mover, which drives the generator and supplies the necessary mechanical power. Understanding the dynamics of the synchronous machine is crucial in comprehending this energy conversion process.

Mechanical To Electrical Energy

This process occurs through the interaction of magnetic fields and the rotation of the generator’s rotor. As the rotor spins, it induces a voltage in the stator windings, which leads to the generation of electrical power.

Synchronous Machine Dynamics

The dynamics of a synchronous machine play a vital role in the energy conversion process. This synchronization ensures efficient power transfer and stability in the electrical grid. Additionally, synchronous machines exhibit unique characteristics, such as the ability to control reactive power and maintain a constant voltage, making them suitable for various applications, including power generation and industrial processes. Overall, the energy conversion process in a synchronous generator relies on the mechanical-to-electrical energy transformation facilitated by the prime mover and the dynamics of the synchronous machine. Understanding these aspects is essential for comprehending the operation and significance of synchronous generators in the generation and distribution of electrical power.

Prime Mover Control Systems

The prime mover control system in a synchronous generator plays a crucial role in regulating the speed and ensuring efficient load sharing. Speed regulation and load sharing mechanisms are two essential aspects of prime mover control systems.

Speed Regulation

This is achieved by adjusting the fuel supply or input power to the prime mover based on the changes in load demand. Different types of speed regulation systems are used in synchronous generators:

- Mechanical Speed Governors: These governors control the fuel supply to the prime mover based on the rotational speed. They use centrifugal force to adjust the throttle opening, ensuring that the speed remains within the desired range.

- Electronic Speed Governors: These governors use electronic sensors to monitor the rotational speed of the prime mover. They can quickly respond to load changes and adjust the fuel supply accordingly, providing more precise speed regulation.

- Hydraulic Speed Governors: These governors utilize hydraulic pressure to control the fuel supply. They are commonly used in large generators where precise speed control is required.

Load Sharing Mechanisms

Load sharing mechanisms are employed in synchronous generators to distribute the electrical load evenly among multiple generators operating in parallel. This ensures that each generator shares the load proportionally, preventing overloading or underloading of any individual generator. Various load sharing mechanisms are used:

- Droop Speed Control: This mechanism adjusts the prime mover’s speed based on the load demand. As the load increases, the speed decreases, allowing more power to be generated. This helps maintain a balanced load sharing among the generators.

- Automatic Voltage Regulator (AVR): The AVR controls the excitation system of the generator, maintaining a constant voltage output. It ensures that all generators produce the same voltage level, promoting equal load sharing.

- Load Sharing Module (LSM): LSMs are electronic devices that monitor the load on each generator and adjust the excitation current to maintain load sharing. They can communicate with other LSMs to coordinate load sharing among multiple generators.

By implementing effective speed regulation and load sharing mechanisms in prime mover control systems, synchronous generators can operate efficiently and maintain stable power output. These control systems play a vital role in ensuring reliable and consistent electricity supply.

Factors Affecting Choice Of Prime Mover

Fuel Availability

The availability of fuel is a crucial factor in selecting a prime mover for a synchronous generator. Different prime movers have varying fuel requirements, and the choice depends on the accessibility and sustainability of the fuel source.

Efficiency And Cost

Efficiency and cost are important considerations when choosing a prime mover for a synchronous generator. The prime mover should offer high efficiency to minimize fuel consumption and operational costs while ensuring reliable power generation.

Operational Flexibility

The operational flexibility of the prime mover is vital for adapting to varying power demands. The ability to quickly adjust output and respond to load changes is essential for maintaining stable power generation.

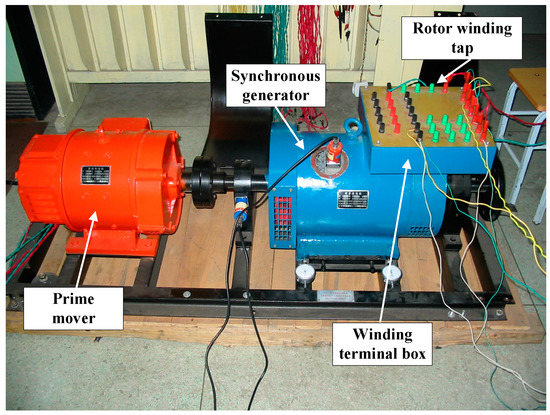

Credit: www.mdpi.com

Challenges In Prime Mover Operation

Operating a prime mover in a synchronous generator poses several challenges. From maintaining speed and load balance to synchronizing with the grid, operators must navigate complex systems to ensure efficient power generation. With careful monitoring and precise adjustments, the prime mover can effectively drive the generator, enabling a reliable and stable electricity supply.

Maintenance And Downtime

Regular maintenance is crucial to prevent breakdowns. Proper upkeep reduces unplanned downtime significantly.

Environmental Concerns

Avoiding pollution and minimizing emissions is essential. Efficient prime mover operation benefits the environment positively. Challenges in Prime Mover Operation: Ensuring prime mover efficiency is key for optimal generator performance. Proper maintenance and addressing environmental concerns are crucial aspects.

Innovations In Prime Mover Technology

Innovations in prime mover technology have greatly impacted the performance of synchronous generators. These advancements have led to increased efficiency and reliability, enhancing the overall operation of the prime mover in generating electricity.

Prime movers play a crucial role in the synchronous generator by providing the necessary mechanical energy to turn the rotor. Innovations in prime mover technology have significantly improved the performance and efficiency of synchronous generators.

Renewable Energy Integration

Renewable energy sources such as wind and solar power have gained significant popularity in recent years. Integrating these sources with synchronous generators requires prime movers capable of handling fluctuations in power output. Innovations in prime mover technology such as variable speed drives and hydraulic transmissions have made it possible to integrate renewable energy sources seamlessly.

Advanced Control Strategies

The performance of synchronous generators depends on the synchronization between the generator and the grid. Advanced control strategies such as model predictive control and adaptive control have been developed to improve the synchronization process. These control strategies require prime movers capable of providing precise and consistent mechanical energy to the generator. In conclusion, innovations in prime mover technology have led to significant improvements in the performance and efficiency of synchronous generators. The integration of renewable energy sources and advanced control strategies has made it possible to generate electricity sustainably and reliably.

Credit: www.researchgate.net

Case Studies

Explore real-world applications of Prime Mover in Synchronous Generator through illuminating case studies. Discover how this essential component drives efficient power generation systems with practical examples and insights.

When it comes to understanding the importance of prime movers in synchronous generators, case studies can provide valuable insights. plants.

Hydroelectric Power Plants

Hydroelectric power plants use water as the prime mover to generate electricity. The prime mover in hydroelectric power plants can be either a water turbine or a hydraulic turbine. The type of turbine used depends on the amount of water available and the head of water.

Thermal Power Stations

Thermal power stations use steam as the prime mover to generate electricity. Steam is produced by heating water using fossil fuels or nuclear energy. The steam then turns the turbine blades, which are connected to the synchronous generator. The prime mover in thermal power stations can be a gas turbine, a steam turbine, or a combined cycle turbine. The type of turbine used depends on the type of fuel used and the efficiency of the power plant.

Nuclear Power Plants

The prime mover in nuclear power plants is a steam turbine. The efficiency of the power plant depends on the type of reactor used and the cooling system. In conclusion, understanding the prime mover in synchronous generators is crucial for the efficient operation of power plants. By analyzing case studies, we can gain valuable insights into the different types of prime movers used in different power plants.

Future Of Prime Movers In Power Generation

The future of prime movers in power generation lies in the continued advancement of synchronous generators. These prime movers play a vital role in converting mechanical energy into electrical energy, and ongoing innovation will enhance their efficiency and sustainability in the power generation sector.

Sustainability Trends

Renewable energy sources are shaping the future of prime movers in power generation.

Smart Grids And Iot

Integration of smart grids and IoT technologies enhance prime mover efficiency.

Frequently Asked Questions

What Is The Prime Mover Of A Synchronous Generator?

The prime mover of a synchronous generator is usually a steam turbine or a gas engine. These drive the generator to produce electricity.

What Is A Prime Mover For A Generator?

A prime mover for a generator is the device that converts mechanical energy into electrical energy. It can be a gas or diesel engine, steam turbine, or water turbine. The prime mover powers the generator, which then produces electricity.

What Is The Function Of The Prime Mover?

The prime mover is responsible for initiating movement in a machine or system efficiently.

Why We Need The Prime Mover In The Synchronous Motor?

The prime mover in synchronous motor is needed to initiate rotation for consistent speed and operation.

Conclusion

The prime mover plays a critical role in synchronous generators, converting mechanical energy into electrical energy. It is important to understand the different types of prime movers available, such as steam turbines, gas turbines, and diesel engines, to ensure the most efficient and effective operation.

Regular maintenance and monitoring are also essential to prolong the lifespan of the prime mover and generator. By prioritizing the upkeep of these components, we can ensure reliable and sustainable power generation for years to come.